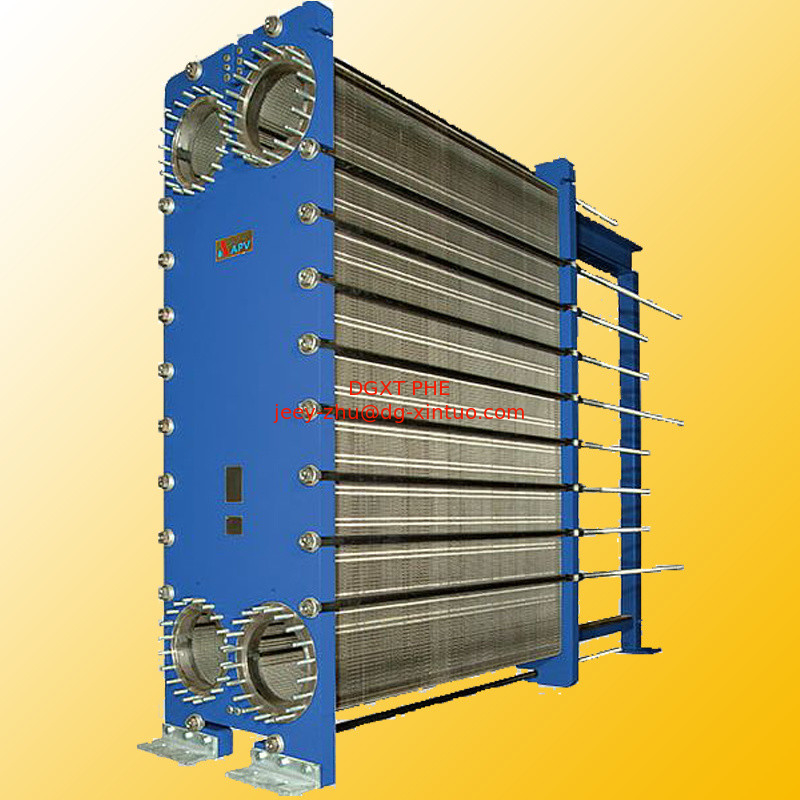

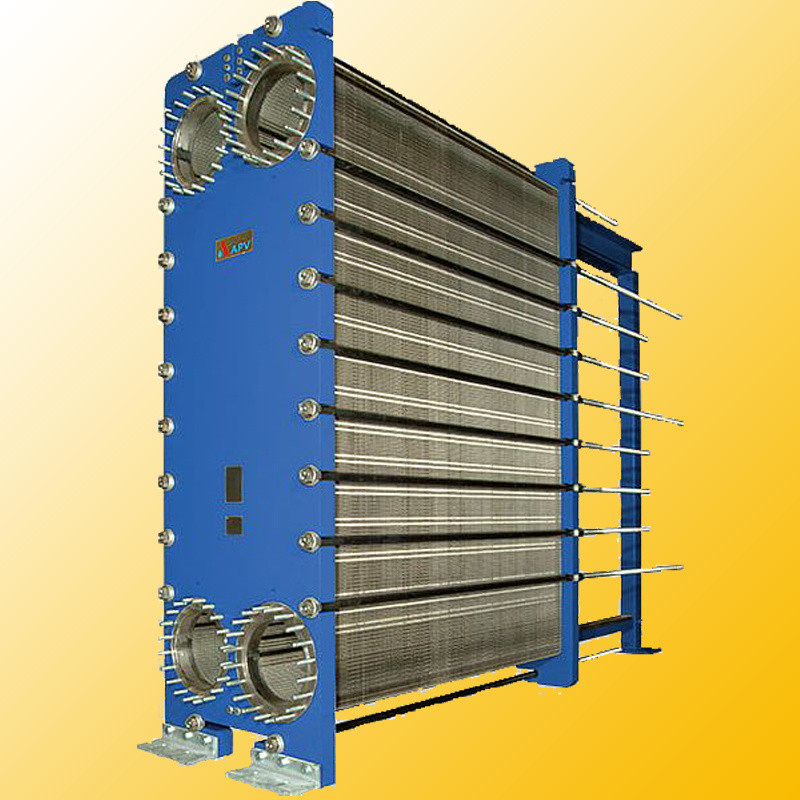

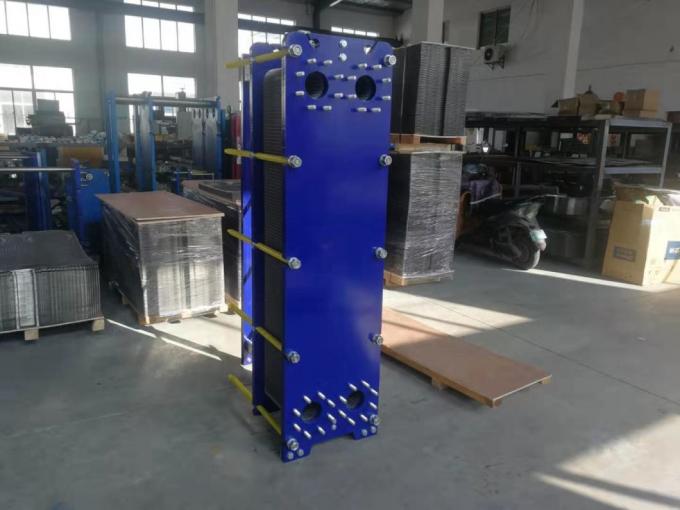

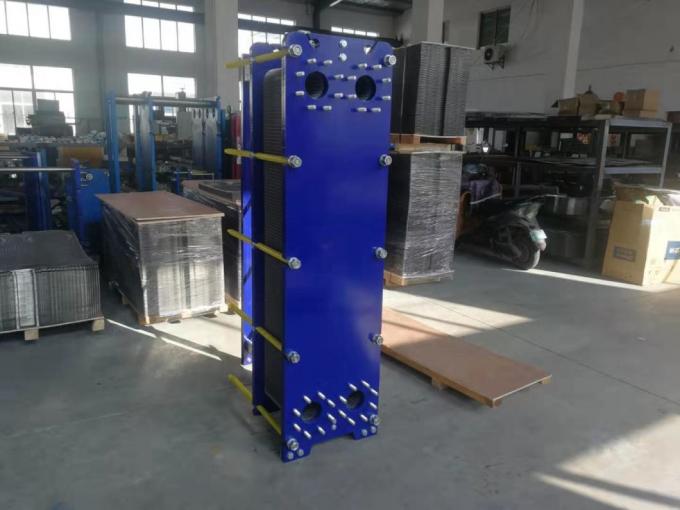

A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids are spread out over the plates.

| Name |

Plate Heat Exchanger |

| Brand |

DGXT |

| MODEL |

Free to selection |

| Plate material |

Stainless steel (AISI304,AISI316) titanium and titanium palladium (Ti, ti-pd),20Cr,18Ni,6Mo(254SMO), nickel (Ni)HASTELLOY alloy |

| Gaster material |

NBR,HNBR, EPDM, FPM, CR, Viton |

| Frame material |

Stainless AISI304/AISI316 or Q235B etc |

| Connect material |

NBR,HNBR,EPDM,stainless AISI304/316 etc |

| Advantage |

1.Sealing gasket is not exposed 2. Advanced plate structure 3. Advanced framework structure 4. Solid sheet thickness

|

| |

|

|

Application:

|

Widely used in petroleum industry, power station, solar photovoltaic, electronic industry, papermaking industry, textile industry, chemical industry, Marine and engine, hvac, food industry, oil processing, metallurgy industry, etc

|

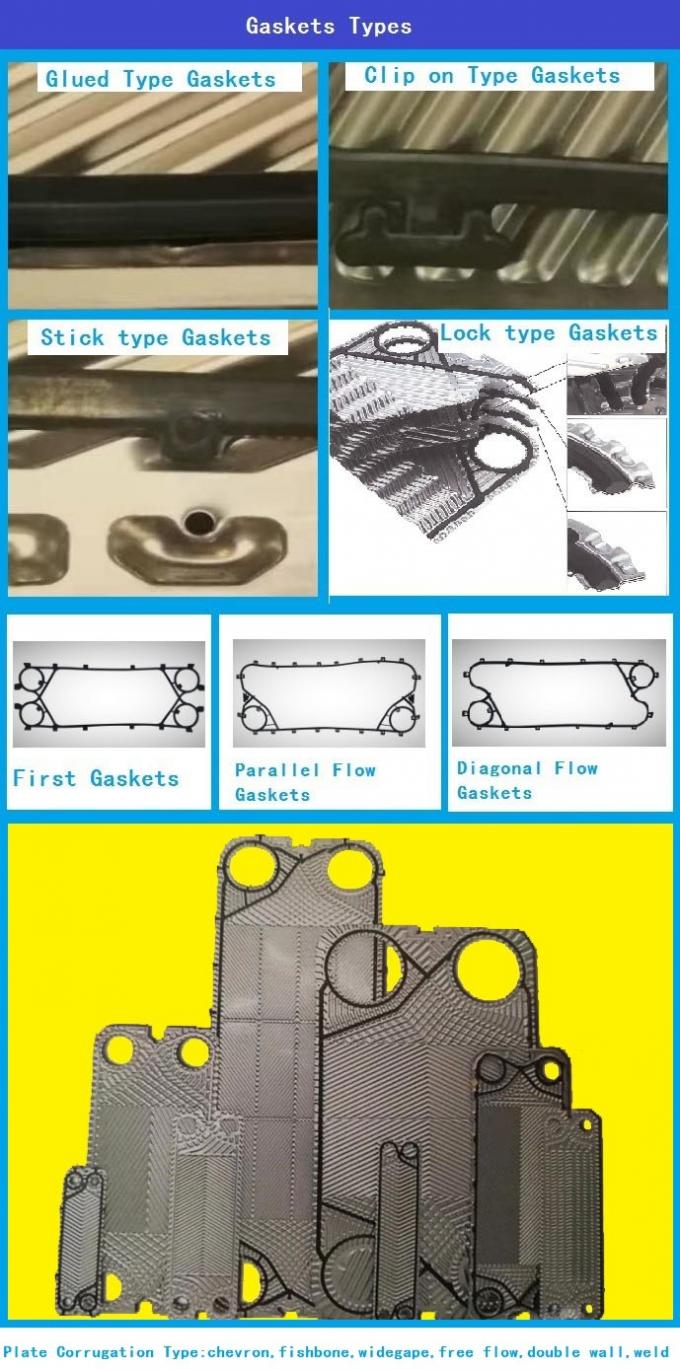

Plate type selection

The plate type or corrugated type shall be determined according to the actual needs of heat exchange occasions. For the case of large flow and small allowable pressure drop, the plate type with small resistance shall be selected, on the contrary, the plate type with large resistance shall be selected. According to the fluid pressure and temperature, decide whether to choose the detachable type or the brazed type. When determining the plate type, the plate with too small single plate area should not be selected to avoid excessive number of plates, small flow rate between plates and low heat transfer coefficient. This problem should be paid more attention to for larger heat exchangers.

Selection of process and runner

Flow refers to a group of parallel flow channels in the same flow direction of a medium in the plate heat exchanger, and the flow channel refers to the medium flow channel composed of two adjacent plates in the plate heat exchanger. Generally, several flow channels are connected in parallel or series to form different combinations of cold and hot medium channels.

The process combination form shall be determined according to the calculation of heat exchange and fluid resistance and meeting the requirements of process conditions. Try to make the convection heat transfer coefficient in the cold and hot water channels equal or close to each other, so as to obtain the best heat transfer effect. Because when the convective heat transfer coefficient on both sides of the heat transfer surface is equal or close, the heat transfer coefficient obtains a larger value. Although the flow velocity between the plates of the plate heat exchanger is different, the average flow velocity is still used in the calculation of heat exchange and fluid resistance. Because the connecting pipes of "U" single process are fixed on the compression plate, it is convenient to disassemble and assemble.

Pressure drop check

In the design and selection of plate heat exchanger, there are certain requirements for pressure drop, so it should be checked. If the check pressure drop exceeds the allowable pressure drop, the design and type selection calculation shall be carried out again until the process requirements are met.

computing method

The calculation of heat transfer coefficient and pressure drop is obtained from the performance curve of products of various manufacturers. The performance curve (criterion correlation) generally comes from the performance test of the product. For the plate type lacking performance test, the criterion correlation of the plate type can also be obtained according to the characteristic geometric size of the plate type through the reference size method, which is adopted by some general software in the world.

Selection software

As for the selection software of plate heat exchanger, the manufacturer has its own selection software according to its own plate type.

Our Advantages:

Our Advantages:

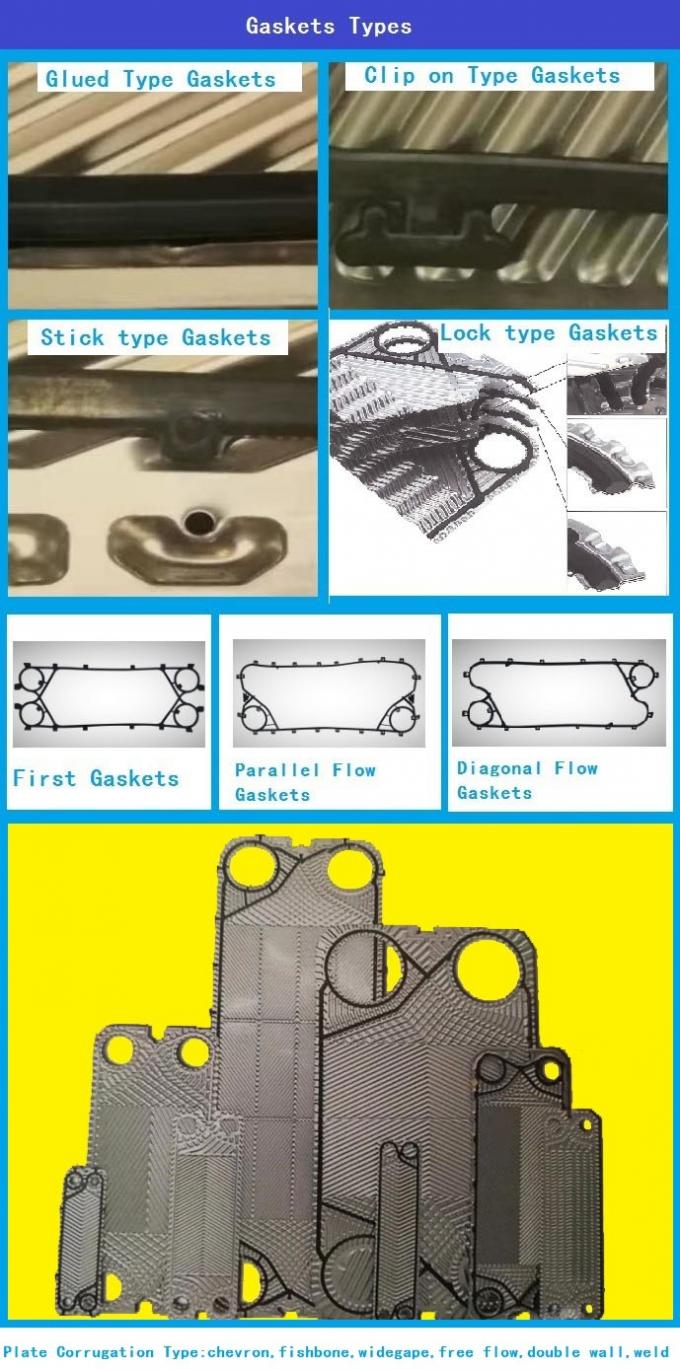

1.we have more than 500 kinds corrugated plates and Plate gaskets

2.Enough plate and gaskets materials for your choose

3.Factory fast delivery once get your deposit payment.

4.Superior Quality in PHE manufacture feilds

5.Each machine will be tested before Packing

6.Our main product range:Gasket plate heat exchanger,Brazed plate heat exchanger,tube plate heat exchager,heat exchanger spares equivalent.

Product material:

1.Frame material: Q235B carbon steel painted ,carbon inner with Pure stain steel out surface,Pure stain steel

2.Port Material : stud bolts with lining,Epdm sleeve,OEM

3.Plate material : stainless steel AISI304/316/Ti /C276/Hastelloy alloy

4.Gasket material : EPDM,NBR,FPM,FKM,Viton etc

5.Plate Thickness: 0.5/0.6mm/others customized

Gaskets Material and avaiable temperature.

| Chemical name |

ASTM D-1418-79 |

Temperature °C |

Temperature °F |

| BUTADIENE - ACRILONITRILE |

NBR STD FOOD |

- 20 + 120 |

-4 + 248 |

| BUTADIENE - ACRILONITRILE |

NBR HT FOOD |

- 20 + 140 |

-4 + 284 |

| BUTADIENE - ACRILONITRILE |

NBR HT IND |

- 20 + 140 |

-4 + 284 |

| BUTADIENE - ACRILONITRILE - IDROGENATA |

H-NBR |

- 40 + 150 |

-40 + 302 |

| CLOROPRENE |

CR |

- 40 + 100 |

-40 + 212 |

| ISOBUTILENE - ISOPRENE |

IIR |

- 40 + 110 |

-40 + 230 |

| ETILENE - PROPILENE - DIENE |

EPDM STD |

- 40 + 120 |

-40 + 248 |

| ETILENE - PROPILENE - DIENE |

EPDM STD FOOD |

- 40 + 120 |

-40 + 248 |

| ETILENE - PROPILENE - DIENE |

EPDM HT FOOD |

- 40 + 150 |

-40 + 302 |

| FLUORURATA |

FKM "A" STD |

- 15 + 220 |

-5 + 428 |

| FLUORURATA |

FKM "A" FOOD |

- 15 + 220 |

-5 + 428 |

| FLUORURATA |

FKM "GF" |

- 8 + 200 |

-17,6 + 392 |

| FLUORURATA |

FKM "GLT" |

- 30 + 200 |

-22 + 392 |

Application:

Heat exchangers use containment vessels to heat or cool one fluid by transferring heat between it and another fluid. Users of heat exchangers include chemical, petrochemical, oil & gas, power generation, refrigeration, pharmaceuticals, HVAC, food & beverage processing and pulp & paper industries.

About Our Company:

About Our Company:

DGXT PHE is headquartered in Local Place. DGXT PHE is dedicated to providing its customers with Reliability, Organization, Safety, and Satisfaction. DGXT PHE understands how important time and savings are to each customer. DGXTPHE will strive to provide each customer with not only a product, but a solution. Let DGXTPHE be the Heat Exchanger Service company you can count on. If you are looking for superior results in a Heat Exchanger Company, DGXTPHE is ready to meet the challenge!

Please feel free to contact with us at any time!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!