Product material:

1.Frame material: commonly carbon steel paint ,carbon inner with stain steel out surface,Pure stain steel frame

2.Port Material : stud bolts with lining,Epdm sleeve,OEM Flange

3.Plate material & thickness : Commonly AISI304/316/Ti /C276 plate 0.5/0.6mm

4.Gasket material : EPDM&NBR&FPM or others.(Most commly use is EPDM)

| Plate material |

Applicable fluids |

| Stainless steel(SU304.316 ect) |

Clean water, river water, edible oil, mineral oil |

| Stainless steel & Ti, Ti-Pd |

Sea water, salty water,salt compounds |

| 20Cr, 18Ni,SMO |

Dilute sulfuric acid,Water solution of salt matter,

Inorganic solution |

| Nickel |

High temperature and high concentration of caustic soda |

| Hastelloy |

Concentrated sulfuric acid,Hydrochloric acid, Phosphoric acid |

| Sealing material: |

adapt temperature |

Suitable for fluid |

| NBR |

-15~+120ºC |

Water, sea water, cooking oil, salt water |

| HNBR |

-15~+140ºC |

High temperature mineral oil, high temperature water |

| EPDM |

-25~+170ºC |

Hot water, water vapor, acid, alkali |

| Viton |

-5~+130ºC |

Acid, alkali, fluid

|

Product Features:

1.Experience the benefit of an individually customized solution that perfectly matches your requirements and lowers your energy consumption.

2.High performance for a low pressure drop eliminates unnecessary burdens on your system and optimizes overall system performance.

3.The design results in a compact solution with a small footprint, simple installation, and easy access for maintenance.

Advanges of Plate Heat Exchanger:

Easy to Remove and Clean

Expandable

High Efficiency

Compact Size

Close Approach Temperature

Multiple Duties in a Single Unit

Less Fouling

Lower Costs

Applications:

- HVAC industry - e.g. district cooling solutions using seawater and groundwater as cooling source - e.g. district heating solutions using, for example, solar and geothermal energy as heating source

- Marine/offshore industry - e.g. central and lubrication oil cooling

- Dairy/food/beverage industry - e.g. pasteurization, heat recoveries, and duties that require gentle treatment

- Sugar industry

- Biogas industry

- Pulp and paper industry

- Heavy industry

- Mining industry

- Petrochemical industry

- Chemical industry - e.g. waste heat recovery from condenser water

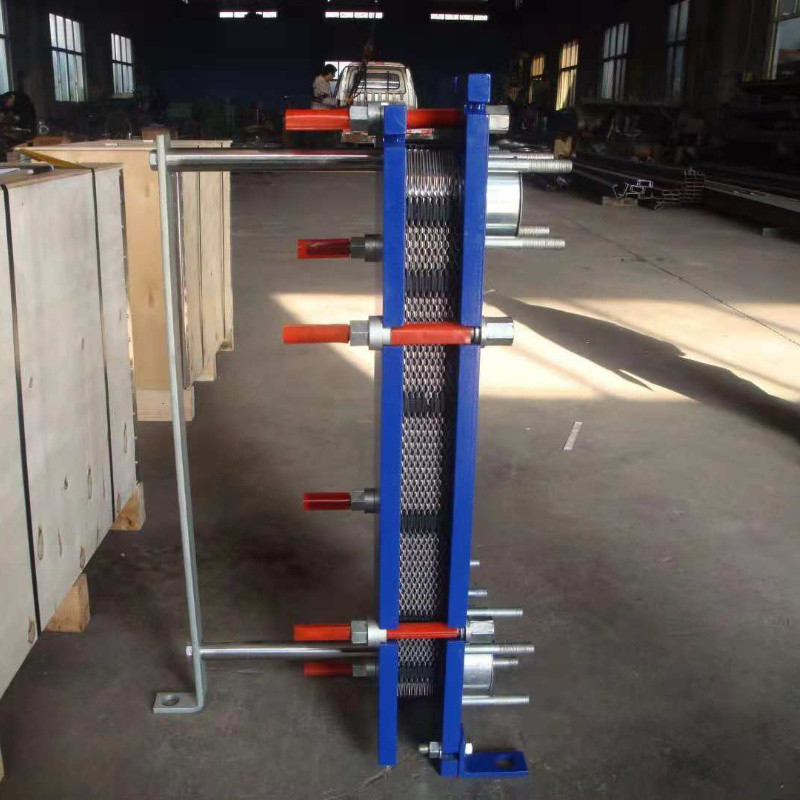

Plate heat exchanger display:

Plate Heat exchanger display:

Plate Heat Exchanger Specification Sheet:

Plate Heat Exchanger Specification Sheet:

Becoming our VIP customers for more plate and gasket models and discounts!

Please Kindly offer us the following PLATE HEAT EXCHANGER informations in your inquiry The more the better.

Type of Plate Heat Exchanger:

Brazed PHE or Gasketed PHE ?

Heat Exchanged:___? (KW,KCAL)

Hot side:

Fluid: ? %40 ethylene glycol , water etc

Temperature inlet: ?

Temperature outlet:?

Flowrate:

Pressure drop:

Cold side:

Fluid: ?

Temperature inlet: ?

Temperature outlet: ?

Flowrate:

Pressure drop:

THANK YOU VERY MUCH FOR YOUR ATTENTION! EXPECTING MORE SERVICE FOR YOU!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!