Plate heat exchangers

| Sealing material: |

adapt temperature |

Suitable for fluid |

| NBR |

-15~+120ºC |

Water, sea water, cooking oil, salt water |

| HNBR |

-15~+140ºC |

High temperature mineral oil, high temperature water |

| EPDM |

-25~+170ºC |

Hot water, water vapor, acid, alkali |

| Viton |

-5~+130ºC |

Acid, alkali, fluid |

| Plate material |

Applicable fluids |

| Stainless steel(SU304.316 ect) |

Clean water, river water, edible oil, mineral oil |

| Stainless steel & Ti, Ti-Pd |

Sea water, salty water,salt compounds |

| 20Cr, 18Ni,SMO |

Dilute sulfuric acid,Water solution of salt matter,

Inorganic solution |

| Nickel |

High temperature and high concentration of caustic soda |

| Hastelloy |

Concentrated sulfuric acid,Hydrochloric acid, Phosphoric acid |

Professional plate heat exchanger manufacturer We can not only provide you with PHE, but also we can design the appropriate plan for heating exchange according to your need. We have 10- year experience of designing in this field and solve various problems for you.We have a wealth of HVAC, refrigeration, metal steel,marine engineering, paper, power,hemical, marine engineering, food and beverage experience.

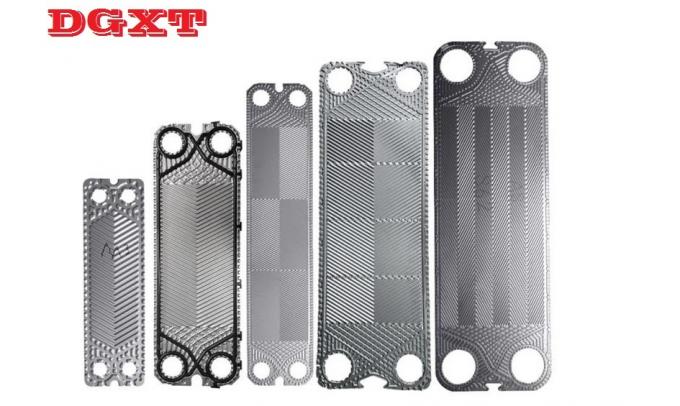

The plate heat exchanger consists of a pack of corrugated metal plates with portholes for the passage of the two fluids between which heat transfer will take place. The plate pack is assembled between a fix frame plate and a movable pressure plate and compressed by tightening bolts. The plates are fitted with a gasket which seals the inter plate channel and directs the fluids into alternate channels. The number of plates is determined by the flow rate, physical properties of the fluids, pressure drop and temperature program. The plate corrugations promote fluid turbulence and support the plates against differential pressure. The frame plate and the pressure plate are suspended from an upper carrying bar and located by a lower guiding bar, both of which are fixed to a support column. Connections are located in the frame plate or, if either or both fluids make more than a single pass within the unit, in the frame and pressure plates.

Working principles

Channels are formed between the plates and the corner ports are arranged so that the two media flow through alternate channels. The heat is transferred through the plate between the channels, and complete counter-current flow is created for highest possible efficiency. The corrugation of the plates provides the passage between the plates, supports each plate against the adjacent one and enhances the turbulence, resulting in efficient heat transfer.

Standard Materials

Frame plate Mild steel,Epoxy painted Metal lined:stainless stell ,titanium Plates Stainless steel alloy304,Stainless steel alloy316 Stainless steel alloy C276 or Titanium or SMO Gaskets Nitrile , EPDM , Viton

Maximum pressure and temperature

All models are available with different frame designs and different plate thickness depending on the required design pressure. The maximum temperature depends on the gasket material used, and the working pressure

What are the advantages of Gasketed Plate Heat Exchanger?

- High heat transfer efficiency

- Low pressure lose

- Compact structure

- Easy assembly & disassembly

- Sensitive temperature control

- High operating flexibility

- Long life-time

Application:

Food industry: Milk pasteurization Milk and beverage pasteurization, Wine tempering, Bottled water treatment, CIP (Cleaning-in-Place) heating, Reverse osmosis water.

Marine application: Central cooling of the main or auxiliary engines or turbines, Lubrication oil cooling, Recooling of circulated water for cooling cylinders, pistons, injection nozzles, Cooling of Baoder oil, compressor oil and other lubricants, Preheating of lubrication oil and heavy fuel oil, Preheating of seawater for fresh water production, Heat recovery, Heat exchange to air-condition the passengers' cabins and freight spaces

Others: Turbine oil cooler, Chemical industry, district heating, district cooling, swimming pool heating, solar heating,

Order any unit from our standard line, and we guarantee delivery within 0-4 weeks, unheard of turnaround times for the industry. We're striving to deliver plate heat exchangers in dramatically shorter times, focusing the experience on the customer.

Our Advantages:

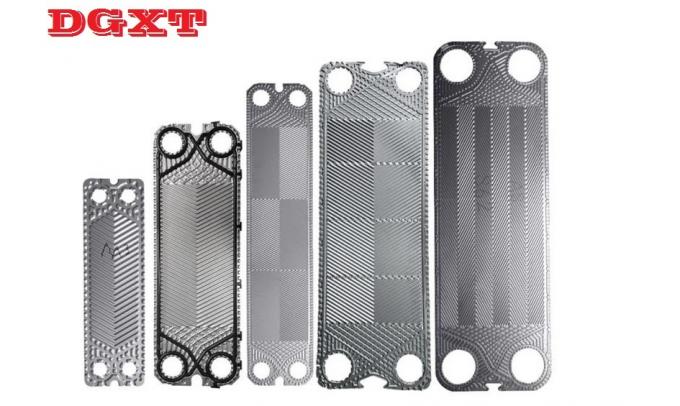

1. Manufacturer and Distributer, we can supply different brands and series plate and gasket, such as Alfa-Lava, APV, GEA, Tranter, SONDEX etc.

2. As manufacturer, we can supply the best quality replace parts for above brands to help you save more cost.

3. Over 10 years' experience in the energy field, we also can provided technical service such as technical consultation, equipment upgrade, capacity expansion scheme, maintenance and cleaning of the equipment.

4. High quality with competitive price, global fast delivery.

5. Our products are superior quality and environment friendly.

6. Prompt response to inquiries and orders.

7. Inventory for standard products.

FACTORY SHOW

FACTORY SHOW

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!