Heat Exchanger Plate Material Choose reference:

| Plate matrial |

Adapt Liquid |

| Stainless steel(304,316) |

Pure water,stem water,Edible oil,mineral oil |

| (Ti,Ti-Pa) |

Sea water,Salt water,Salt compounds |

| 20Cr,18Ni,6Mo(2455Mo) |

Dilute sulfuric acid, dilute sulfate, organic water solution |

| (Ni) |

High Temperature and High Concentration Caustic Sodium |

| HASTELLOY(C276,D25,B2G) |

Concentrated sulfuric acid, hydrochloric acid and phosphoric acid |

Heat Exchanger Plate gaskets Material Choose reference:

| Sealing material: |

adapt temperature |

Suitable for fluid |

| NBR |

-15~+120ºC |

Water, sea water, cooking oil, salt water |

| HNBR |

-15~+140ºC |

High temperature mineral oil, high temperature water |

| EPDM |

-25~+170ºC |

Hot water, water vapor, acid, alkali |

| Viton |

-5~+130ºC |

Acid, alkali, fluid |

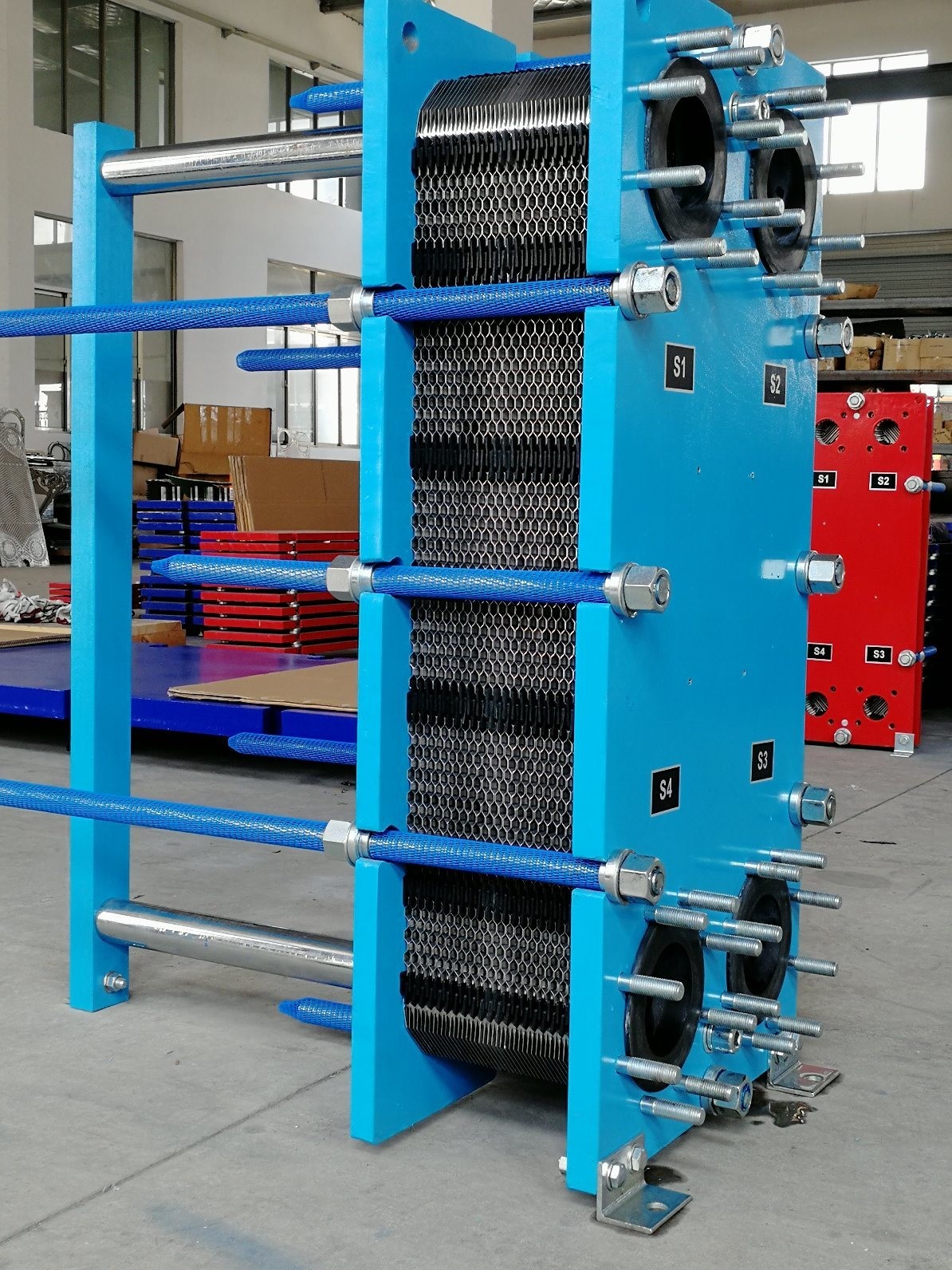

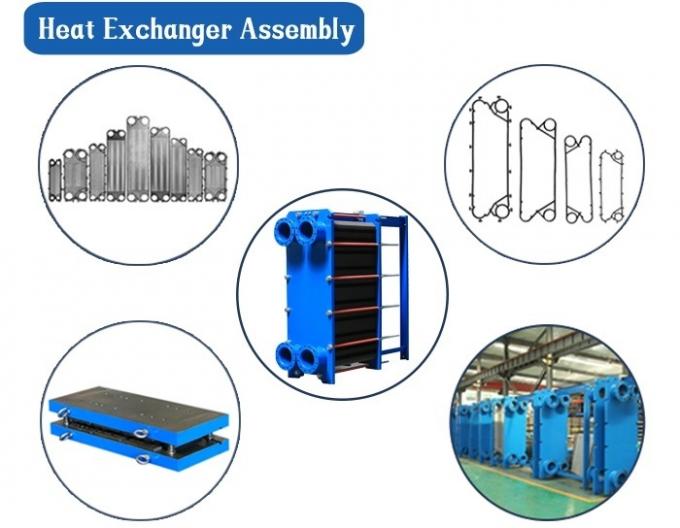

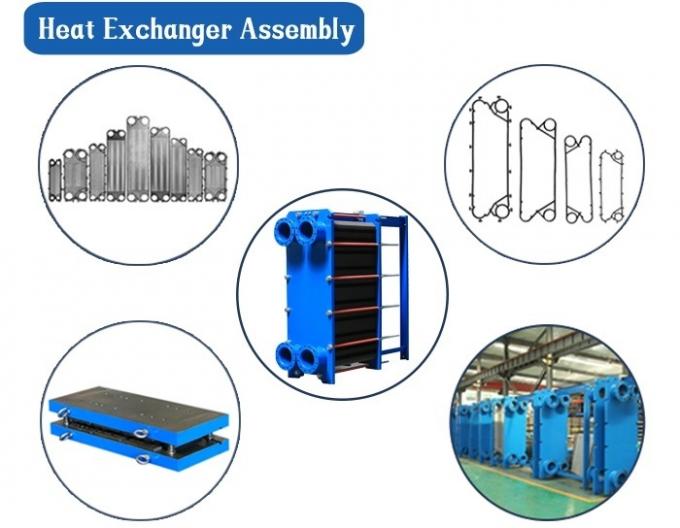

The basic composition structure is shown in the figure:

Plate heat exchanger

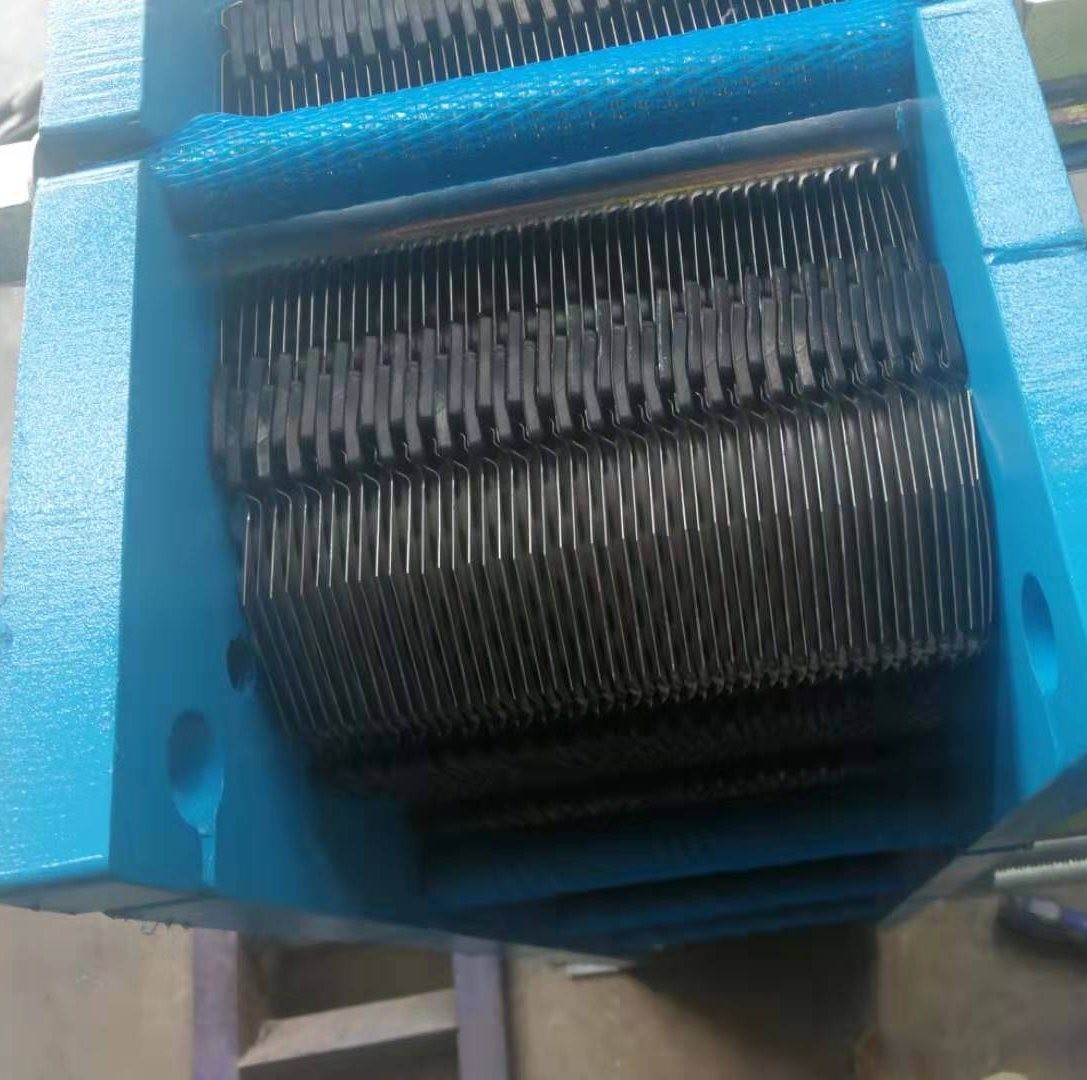

1. Plate of plate heat exchanger and sealing gasket of plate heat exchanger

2. Fix the pressing plate

3. Movable pressing plate

4. Clamping bolt

5. Upper guide rod

⒍ lower guide rod

⒎ rear column

Features:

a. High heat transfer coefficient

b. The logarithmic average temperature difference is large and the terminal temperature difference is small

c. Small floor area

d. It is easy to change the heat exchange area or process combination

e. Light weight

f. Low price

g. Easy to make

h. Easy to clean

i. Small heat loss

j. Small capacity

l. Not easy to scale

m. The working pressure should not be too high, and leakage may occur

n. Easy to jam

Plate type selection

The plate type or corrugated type shall be determined according to the actual needs of heat exchange occasions. For the case of large flow and small allowable pressure drop, the plate type with small resistance shall be selected, on the contrary, the plate type with large resistance shall be selected. According to the fluid pressure and temperature, decide whether to choose the detachable type or the brazed type. When determining the plate type, the plate with too small single plate area should not be selected to avoid excessive number of plates, small flow rate between plates and low heat transfer coefficient. This problem should be paid more attention to for larger heat exchangers.

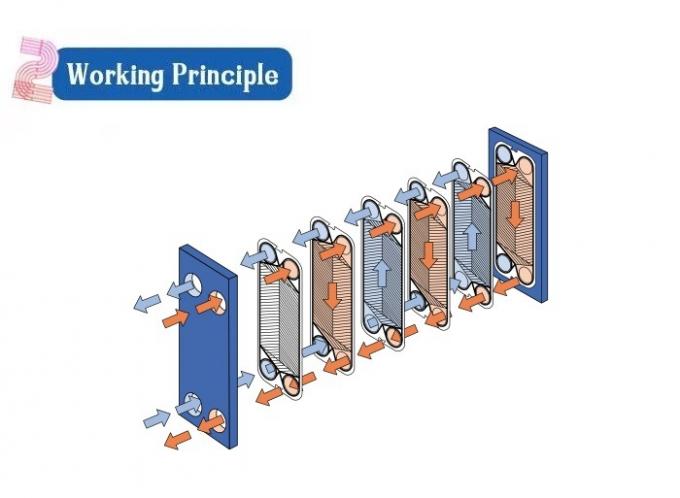

Selection of process and runner

Flow refers to a group of parallel flow channels in the same flow direction of a medium in the plate heat exchanger, and the flow channel refers to the medium flow channel composed of two adjacent plates in the plate heat exchanger. Generally, several flow channels are connected in parallel or series to form different combinations of cold and hot medium channels.

The process combination form shall be determined according to the calculation of heat exchange and fluid resistance and meeting the requirements of process conditions. Try to make the convection heat transfer coefficient in the cold and hot water channels equal or close to each other, so as to obtain the best heat transfer effect. Because when the convective heat transfer coefficient on both sides of the heat transfer surface is equal or close, the heat transfer coefficient obtains a larger value. Although the flow velocity between the plates of the plate heat exchanger is different, the average flow velocity is still used in the calculation of heat exchange and fluid resistance. Because the connecting pipes of "U" single process are fixed on the compression plate, it is convenient to disassemble and assemble.

Pressure drop check

In the design and selection of plate heat exchanger, there are certain requirements for pressure drop, so it should be checked. If the check pressure drop exceeds the allowable pressure drop, the design and type selection calculation shall be carried out again until the process requirements are met.

Computing method

The calculation of heat transfer coefficient and pressure drop is obtained from the performance curve of products of various manufacturers. The performance curve (criterion correlation) generally comes from the performance test of the product. For the plate type lacking performance test, the criterion correlation of the plate type can also be obtained according to the characteristic geometric size of the plate type through the reference size method, which is adopted by some general software in the world.

Selection software

As for the selection software of plate heat exchanger, the manufacturer has its own selection software according to its own plate type.

Note:we help to build the project solutions about the plate heat exchanger.

Small Order qty less than 5 pcs , Product will be delivery at first time with in 12 days.

Features: Compact structure, small area, good heat transfer effect, small pressure drop, a variety of fillers, good corrosion resistance, especially in the treatment of foamy materials and vacuum operation, has its unique advantages.

Advantages:

1.high heat transfer efficiency,

2.large logarithmic temperature difference,

3.light weight, small area, convenient cleaning, and easy to change the heat area or process combination, 4.suitable for heat transfer in multiple media.

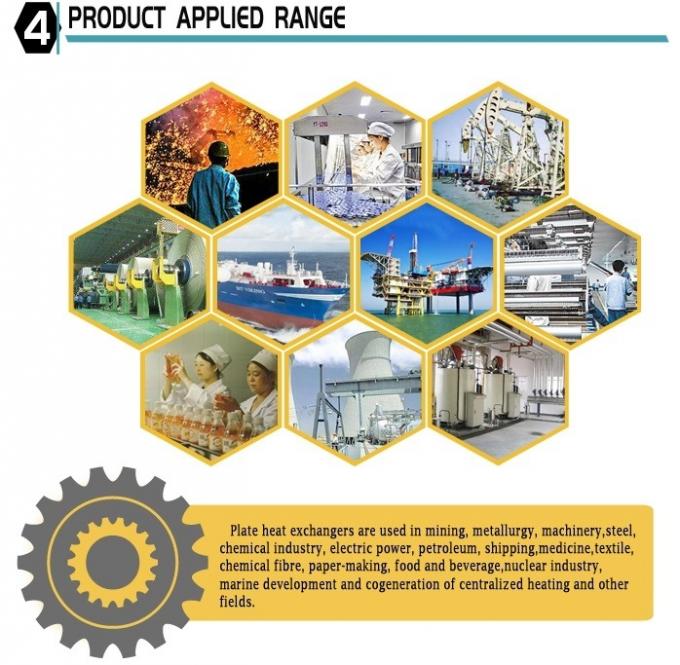

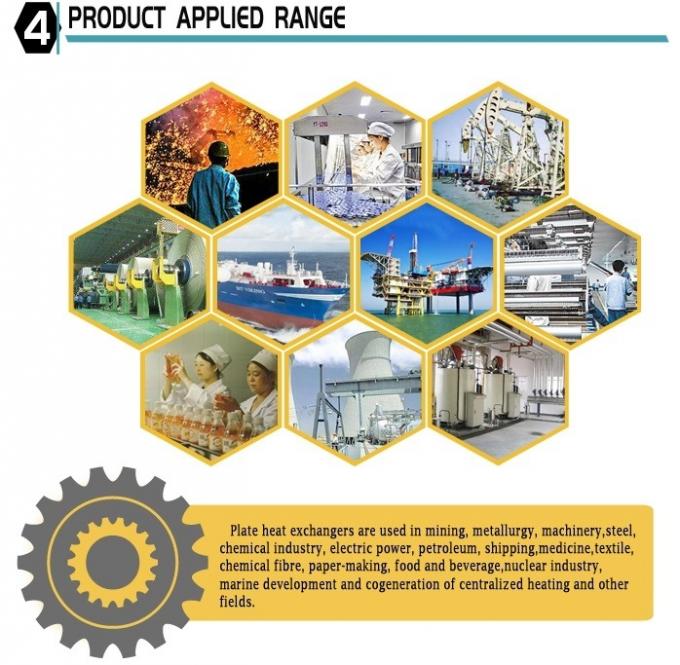

Application: Widely used in the petroleum industry, power station, solar photovoltaic, electronics industry, papermaking industry, textile industry, chemical industry, marine and engine, HVAC, food industry, edible oil processing, metallurgical industry and so on.

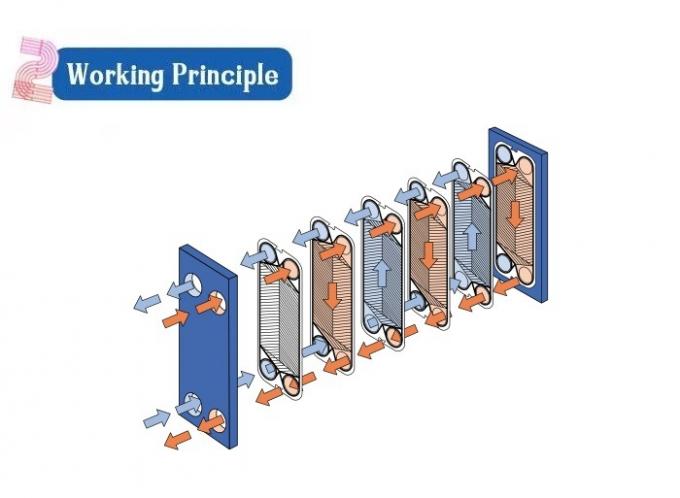

Role: Heat exchanger is a device that transmits heat from a hot fluid to a cold fluid, also known as a heat exchanger. Its main function is to guarantee the specific temperature required by the process for the medium.

It can transfer heat between materials between two or more fluids at different temperatures, transfer heat from a higher temperature fluid to a lower temperature fluid, and bring the fluid temperature to meet the flow specifications to meet the needs of the process conditions., At the same time, heat exchanger is also one of the main equipment to improve energy efficiency.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!