Heat Exchanger Plate Material Choose reference:

| Plate matrial |

Adapt Liquid |

| Stainless steel(304,316) |

Pure water,stem water,Edible oil,mineral oil |

| (Ti,Ti-Pa) |

Sea water,Salt water,Salt compounds |

| 20Cr,18Ni,6Mo(2455Mo) |

Dilute sulfuric acid, dilute sulfate, organic water solution |

| (Ni) |

High Temperature and High Concentration Caustic Sodium |

| HASTELLOY(C276,D25,B2G) |

Concentrated sulfuric acid, hydrochloric acid and phosphoric acid |

Heat Exchanger Plate gaskets Material Choose reference:

| Sealing material: |

adapt temperature |

Suitable for fluid |

| NBR |

-15~+120ºC |

Water, sea water, cooking oil, salt water |

| HNBR |

-15~+140ºC |

High temperature mineral oil, high temperature water |

| EPDM |

-25~+170ºC |

Hot water, water vapor, acid, alkali |

| Viton |

-5~+130ºC |

Acid, alkali, fluid |

We Supply all kinds of heat exchanger replacement plate and gaskets service,completed machine service.

including Gea, Apv, Funke, Hisaka, Muller, Sondex, Thermowave, etc

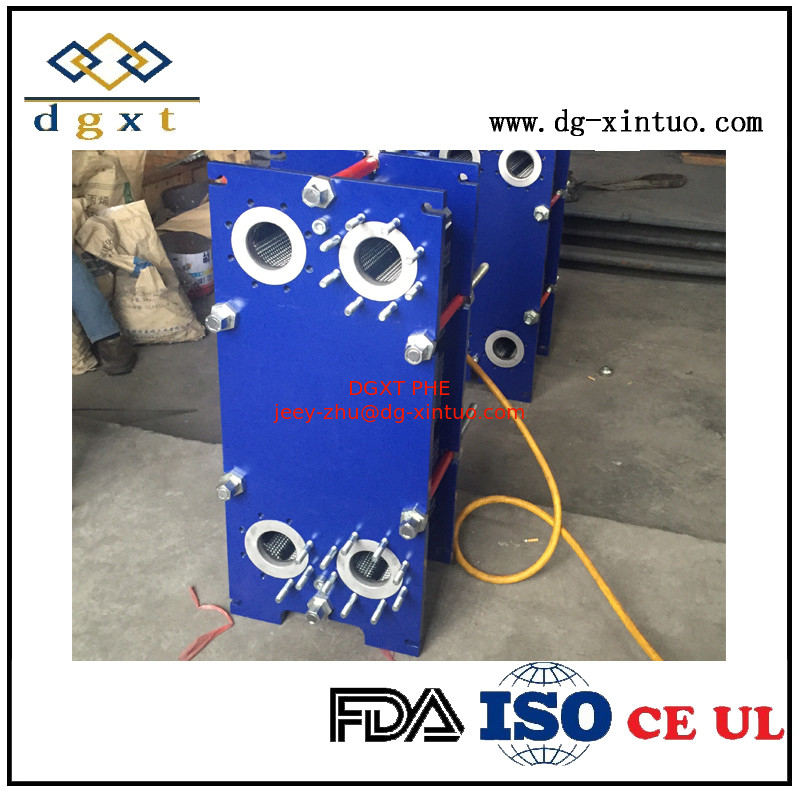

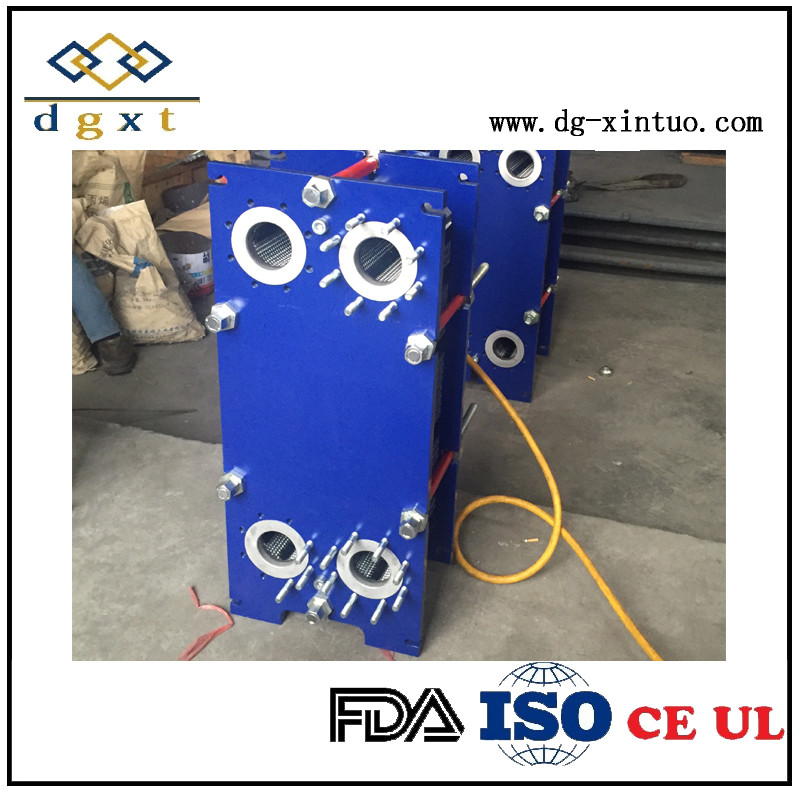

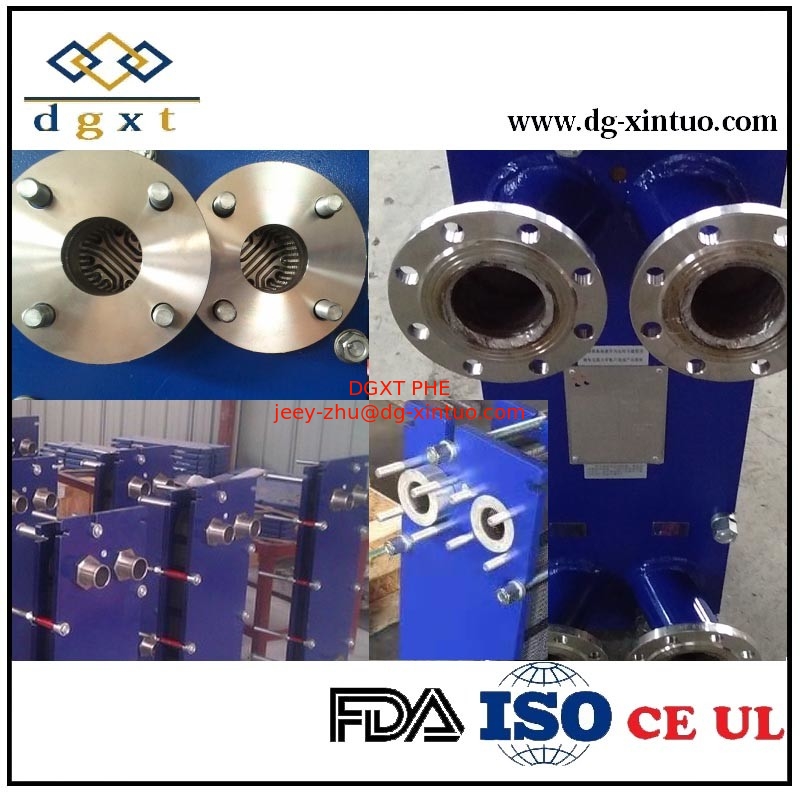

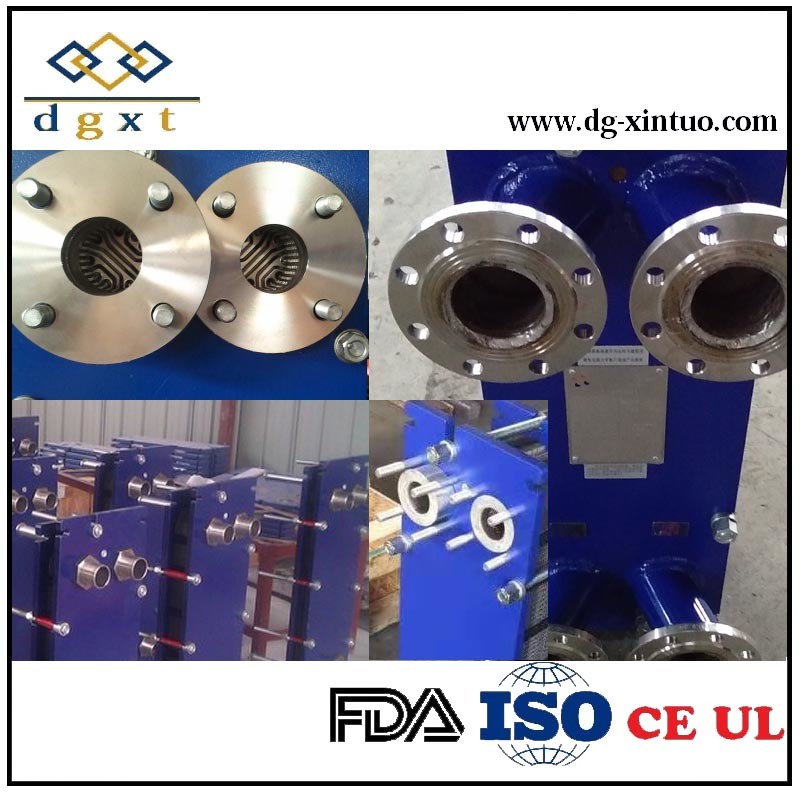

The frame includes a fixed compression plate and a movable compression plate, which are supported by the upper guide rod and the lower guide rod, and have a pillar at the other end. The two mediums flow into the respective channels consisting of corrugated plates through the flange holes on the fixed (or movable) compression plate, and the medium flows out from the flange holes on the fixed (or movable) compression plate after the heat exchange. The same fixed pressure plate, movable pressure plate, pillar and guide are all low carbon steel. Considering the user's various requirements, there are many types of frame designs, including the double-supported frame type and the commonly used floor type.

Heat transfer plates are one of the core components of plate heat exchangers. The corrugated sheet is formed by pressing, and the reasonable corrugated design increases the effective heat transfer area of the sheet, so that the fluid forms turbulence when passing along the corrugation, which strengthens the heat transfer process. A sealing gasket is arranged on the sealing groove of the corrugated plate, and the sealing gasket is designed as a double-channel sealing structure and has a signal hole. Sealing gasket can be selected according to different fluids and operating temperatures.

Work principle

Fluid A passes from the port on the left of the heat exchanger through every other channel created by the plates to the opposite end port on the left of the heat exchanger (looking at it the long way).

Corrosion

Corrosion is usually how these units will fail. Use fluids with reasonable pH levels to ensure a long lasting life. Hard water will corrode faster than regular water. (Use distilled if possible;

Application

Refrigeration system

Evaporator

Condenser

Economizer and desuperheaters

Air drier

Heat pump

Absorption chiller

HVAC

Radiant floor

Provide all of the following model

D-Sondex Plate Heat Exchanger Model

|

| Detachable Sondex plate heat exchanger specification |

| Model |

Connection |

surface/plate |

Plate QTY |

QMAX |

Surface max |

| |

DN |

m2 |

No. |

T/H |

m2 |

| D-S7 |

50 |

0.07 |

76 |

40 |

5 |

| D-S14 |

50 |

0.15 |

427 |

40 |

59 |

| D-S17 |

50/65 |

0.19 |

609 |

40 |

100 |

| D-S18 |

50/62.5 |

0.19 |

609 |

65 |

115 |

| D-S21 |

100 |

0.22 |

698 |

180 |

146 |

| D-S22 |

100 |

0.26 |

538 |

165 |

118 |

| D-S41 |

150 |

0.45 |

670 |

380 |

274 |

| D-S42 |

150 |

0.46 |

532 |

360 |

223 |

| D-S62 |

150 |

0.68 |

670 |

380 |

415 |

| D-S43 |

200 |

0.46 |

695 |

700 |

300 |

| D-S65 |

200 |

0.68 |

695 |

700 |

450 |

| D-S100 |

200 |

1 |

695 |

700 |

695 |

| D-S130 |

200 |

1.3 |

695 |

700 |

900 |

| D-S80 |

300 |

0.8 |

930 |

1600 |

744 |

| D-S81 |

300 |

0.84 |

930 |

1600 |

750 |

| D-S120 |

300 |

1.2 |

930 |

1600 |

1115 |

| D-S188 |

300 |

1.88 |

930 |

1600 |

1750 |

| 300 |

1.88 |

930 |

1600 |

2210 |

| D-S250 |

300 |

2.51 |

930 |

1600 |

2334 |

| D-S200 |

500 |

2.06 |

930 |

4000 |

1860 |

| The Table are Sondex Commonly type Pressure Up to 2.5Mpa |

| Frame type:IS,IT,FT,IG,FS,FG,IC |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!