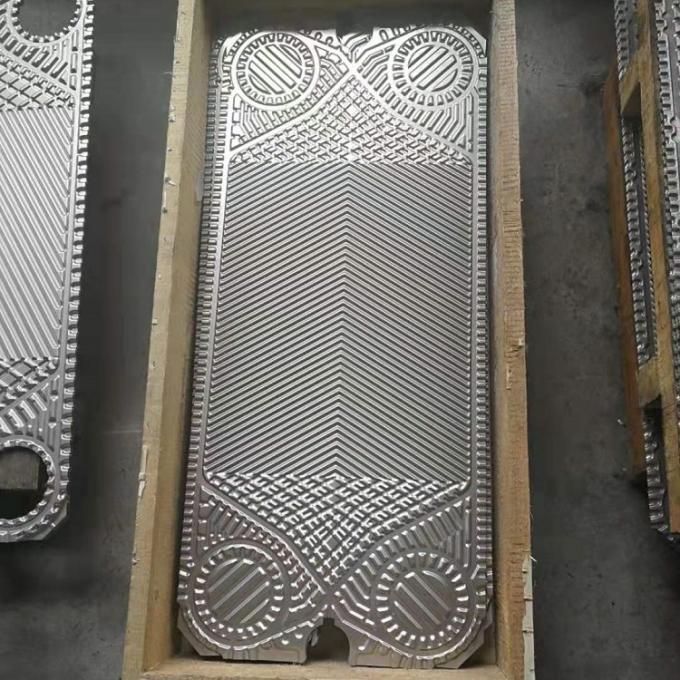

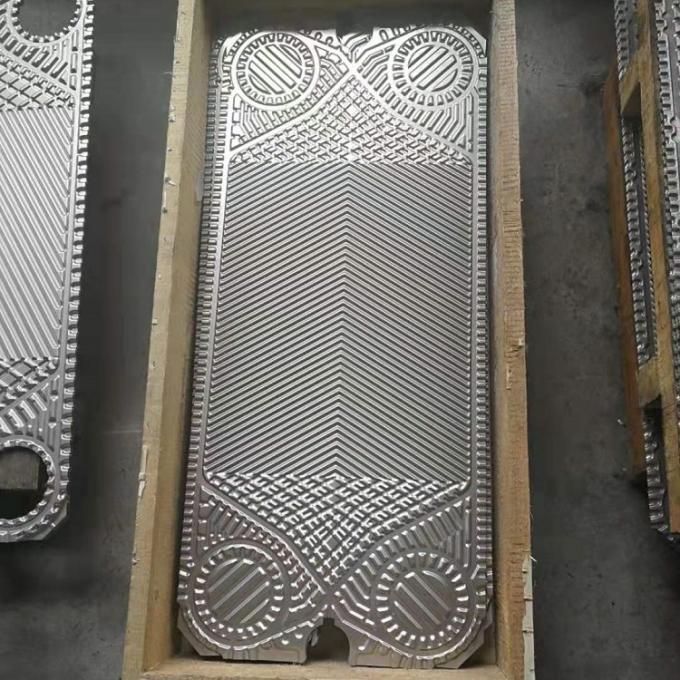

1.100% equivalent can replace original brand plate.

2.Top high quality reach to export standard

3.Fast delivery save each customers' time

4.Supply Product : Heat exchanger plate,Heat exchanger gaskets,copper brazed heat exchanger,tube heat exchanger,gasket plate heat exchanger

5.Standard export packing wooden case,Product wont be damaged,broken at any conditions

6.Brands including including Gea, Apv, Funke, Hisaka, Muller, Sondex, Thermowave, tranter ,etc

Product introduction:

1.Metal material:304/316/Titanium /254 SMO/Alloy C-276/904L oem welcome

2. Gaskets:Nitrile- EPDM- FKM

3.Application: Heat exchanger

High effectient heating and Cooler

Heat Exchanger Plate Material Choose reference:

| Plate matrial |

Adapt Liquid |

| Stainless steel(304,316) |

Pure water,stem water,Edible oil,mineral oil |

| (Ti,Ti-Pa) |

Sea water,Salt water,Salt compounds |

| 20Cr,18Ni,6Mo(2455Mo) |

Dilute sulfuric acid, dilute sulfate, organic water solution |

| (Ni) |

High Temperature and High Concentration Caustic Sodium |

| HASTELLOY(C276,D25,B2G) |

Concentrated sulfuric acid, hydrochloric acid and phosphoric acid |

Heat Exchanger Plate gaskets Material Choose reference:

| Sealing material: |

adapt temperature |

Suitable for fluid |

| NBR |

-15~+120ºC |

Water, sea water, cooking oil, salt water |

| HNBR |

-15~+140ºC |

High temperature mineral oil, high temperature water |

| EPDM |

-25~+170ºC |

Hot water, water vapor, acid, alkali |

| Viton |

-5~+180ºC |

Acid, alkali, fluid

|

We Supply all kinds of heat exchanger replacement plate and gaskets service,completed machine service.

including Gea, Apv, Funke, Hisaka, Muller, Sondex, Thermowave, etc

Plate Heat Exchangers

welcome to inquiry us for plate heat exchanger,we supply plate heat exchanger based on your project work situation or Product drawing.

Standard materials

Frame plate: Mild steel, painted

Nozzles Material :Stainless steel AISI 316 or Titanium

Plates Material : Stainless steel AISI 316 or Titanium

Gaskets Material : EPDM/HEPDM NBR/HNBR Viton,Viton A, Viton G

Connections : 2 " NPT OR OEM

Hot water plate heat exchanger

Function of a Plate Heat Exchanger

A plate Heat Exchanger is a unit which transfers heat continuously from one media to another media without adding energy to the process. The basic concept of a plate and frame Heat Exchanger is two liquids flowing on either side of a thin corrugated metal plate so heat may be easily transferred between the two.

The plates are compressed by means of tie bolts between a stationary frame part (called the head) and a movable frame part (called the follower).

The plate Heat Exchanger efficiency requires less floor space compared to other types of Heat Transfer equipment and is lighter in weight.

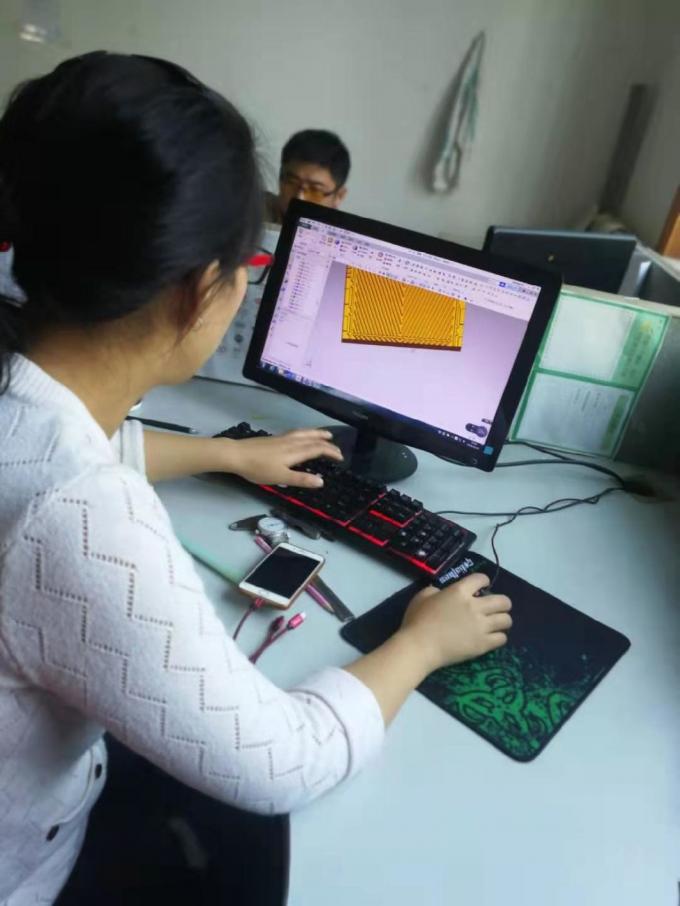

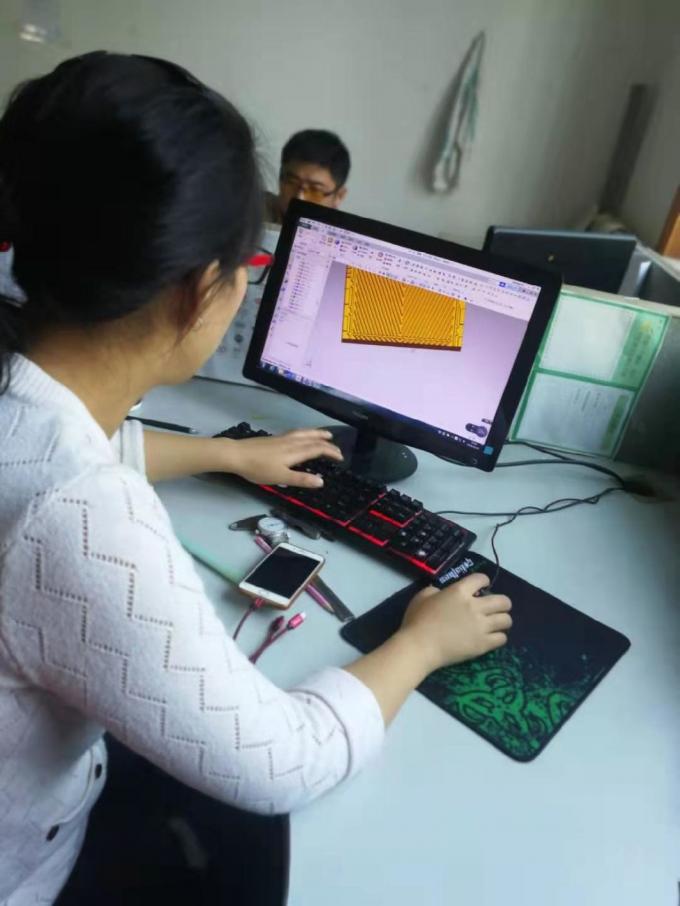

Design of a Plate Heat Exchanger

The plate Heat Exchanger is designed with either single-pass or multi-pass flow, depending on the duty. For most duties single-pass is suitable and often the preferred solution as it keeps all connections on the stationary frame part and consequently makes disassembly easier. Multi-Pass however, is required when flow rates are low or when approach temperatures are close. Other factors such as building ceiling height or space limitations for handling of large plates often leads to the decision to use multi-pass and thereby more and smaller plates.

Advanges of Plate Heat Exchangers

Easy to Remove and Clean

Expandable

High Efficiency

Compact Size

Close Approach Temperature

Multiple Duties in a Single Unit

Less Fouling

Lower Costs

Features and benefits

Experience the benefit of an individually customized solution that perfectly matches your requirements and lowers your energy consumption.

High performance for a low pressure drop eliminates unnecessary burdens on your system and optimizes overall system performance.

The design results in a compact solution with a small footprint, simple installation, and easy access for maintenance.

Applications

- HVAC industry - e.g. district cooling solutions using seawater and groundwater as cooling source - e.g. district heating solutions using, for example, solar and geothermal energy as heating source

- Marine/offshore industry - e.g. central and lubrication oil cooling

- Dairy/food/beverage industry - e.g. pasteurization, heat recoveries, and duties that require gentle treatment

- Sugar industry

- Biogas industry

- Pulp and paper industry

- Heavy industry

- Mining industry

- Petrochemical industry

- Chemical industry - e.g. waste heat recovery from condenser water

| Plate material |

Applicable fluids |

| Stainless steel(SU304.316 ect) |

Clean water, river water, edible oil, mineral oil |

| Stainless steel & Ti, Ti-Pd |

Sea water, salty water,salt compounds |

| 20Cr, 18Ni,SMO |

Dilute sulfuric acid,Water solution of salt matter,

Inorganic solution |

| Nickel |

High temperature and high concentration of caustic soda |

| Hastelloy |

Concentrated sulfuric acid,Hydrochloric acid, Phosphoric acid |

| Sealing material: |

adapt temperature |

Suitable for fluid |

| NBR |

-15~+120ºC |

Water, sea water, cooking oil, salt water |

| HNBR |

-15~+140ºC |

High temperature mineral oil, high temperature water |

| EPDM |

-25~+170ºC |

Hot water, water vapor, acid, alkali |

| Viton |

-5~+130ºC |

Acid, alkali, fluid |

More our products display:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!